rockwell hardness test lab report discussion|rockwell hardness test calculation : fabrication The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

Grand Theft Auto V é um jogo eletrônico de ação-aventura desenvolvido pela Rockstar North e publicado pela Rockstar Games. É o sétimo título principal da série Grand Theft Auto e foi lançado originalm.

{plog:ftitle_list}

Resultado da 01. MYTHS // Iso Agent Trailer - VALORANT. Iso Official Gameplay Reveal // VALORANT. Riot Games presents VALORANT: a 5v5 character-based .

Rockwell hardness tester gives the direct reading of a hardness number on a dial provided with the machine. Specifications are as follows: Ability to determine the hardness up to 100 RHN. .

The Rockwell Hardness Test Method, as defined in ASTM E-18 is the most used .The Rockwell Hardness Test Method, as defined in ASTM E-18 is the most used hardness test. It is easy to perform, and more accurate than other types of hardness tests. In our lab, we used Rockwell method to measure the .Rockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are .

Indentation test is one of the prominently used hardness testing method where we apply a certain predefined load with the help of an indenter which penetrates into the sample surface; .

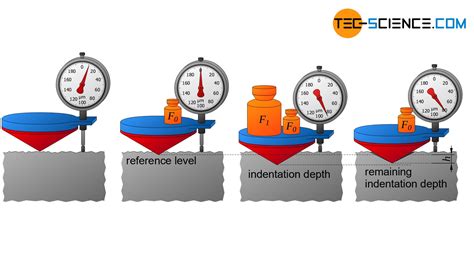

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inverselyThe Rockwell hardness test measures hardness by pressing an indenter into the material surface under a speci c load and then measuring the depth of penetration. Other tests like . The Rockwell hardness test is an indentation test that measures the deformation that occurs when the material is penetrated with a specific type of indenter, which indicates the .

Lab report - Have students report, presenting their results and discussing any variables involved in differences in measurements and literature in order to reiterate the key concepts involved in .Rockwell hardness test. Use ASTM E 140-88 "Standard Hardness Conversion Tables for Metals (Relationship Between Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell .

Objective The experiment focuses on measuring the hardness of a metal using both conventional Rockwell hardness and Knoop microhardness testing techniques. In the process, learners get to understand the concept of hardness and why it can be related to the yield/tensile strengths of the metal. Equipment • Rockwell Testing: Aluminum (2024) (B .

Bogazici University Materials Science Course - Hardness Tests Lab Report. Deniz Akyazı. This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness . 5. PAGE 4 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between .Infinita Lab leads the way in material science, offering a wide selection of over 2,000 tests across various industries, including the widely recognized Rockwell hardness test. This essential evaluation, pivotal for determining material hardness, particularly in metals, examines the depth of penetration by an indenter under different loads. ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

Table 4 - Rockwell Hardness Test data and results Rockwell Hardness Test Data and Results Type of Material 1020 Steel 2024 Aluminum 6061 Aluminum Test No. Diameter (mm) 1 91.7 77.7 58.9 2 93.0 78.2 58.6 3 93.0 79.0 58.1 4 93.2 78.9 59.1 5 93.0 78.0 59.0 Mean 92.8 78.4 58.7 Tensile Strength (psi) 96071 71750 51360 Reference RHN** 88 75 60 .

rockwell hardness testing method

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

Hardness Testing Lab (Brinell and Rockwell), 2020. . Bogazici University Materials Science Course - Hardness Tests Lab Report. . RESULTS & DISCUSSION Results Parameters First Reading Second Reading Third Reading D1 (µm) 153.1 151.7 153.5 D2 (µm) 159.0 151.7 153.5 Hardness (HV) 152.3 161.1 157.4 Average Hardness (HV) 156.9 Calculations .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . This article discusses rockwell hardness testing, its applications and uses. . a bachelor’s degree in journalism from Buffalo State College and has 8 years of experience working in a professional laboratory. . paper or report: APA. Smith, Brett. (2020, December 08). An Introduction to Rockwell Hardness Testing. AZoM. Retrieved on October .

PDF | On Aug 27, 2023, Dokta Urame published EN113 Lab 02 Brinell Hardness Testing Report | Find, read and cite all the research you need on ResearchGate

This document describes procedures for harness testing of metallic materials using the Rockwell scale. The Rockwell hardness test measures the indentation made by specific loads on a material's surface. There are different Rockwell scales that use varying loads and indenters depending on the material. The experiment uses a Rockwell hardness tester with a diamond .Rockwell Hardness Test per ASTM E18 "Standard Test Method for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials" • Place the cylindrical gripped end of one half of a fractured tensile specimen of one of the materials in the V-notched platen of the Rockwell hardness tester.Rockwell hardness test rockwell hardness test lab report submitted : salman tariq 170301006 abdur rahman khan 170301014 faizan khan 170301026 submitted to: engr. Skip to document. University; High School; . Lab report of dpt - NIL; Paper 63; .Rockwell Hardness Testing Lab Report Sample; Rockwell Hardness Testing Lab Report Sample. 1123 Words 5 Pages. EXPERIMENTAL PROCEDURE The specimen Al 2024 which was consist of 3.8-4.9% Cu, 1.2-1.8% Mg, 0.3-0.9% Mn, and Fe, Cr, Zn, Ti in a little amount had been inserted into a furnace set at 500oC approximately 50 minutes for a solution .

4) For Rockwell hardness testing, no optical measurements are required; all readings are direct. There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinelllab report on rockwell hardness test lab strain hardening abstract in the experiment, we examined the effect that strain hardening has on metals. we did this . The percent coldwork is 11%. Final hardness is 1 03ß. DISCUSSION .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Rockwell hardness testing machine (b)Theory There are many de nitions for hardness depending on the material. For metals, the most appropriate one would be ‘resistance to permanent deformation’. Hardness can be calculated in many ways and using many tests. The Rockwell hardness test measures hardness by pressing an indenter into the .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .ROCKWELL HARDNESS TEST: This hardness test uses a direct reading instrument based on the principle of differential depth measurement. Rockwell testing differs from Brinell testing in that the . Attach the table as an appendix to your lab report!) 2. Using the above converted values, calculate the UTS and YS values using the empirical

As part of the first lab, Brinell Hardness test will be used to determine the level of hardness applied from a 10 mm steel ball indenter onto a steel and aluminum disc under different applied force. EQUIPMENT & PROCEDURE The laboratory report is about two experiments: Microstructure examination and Hardness test. I n hardness test three different specimens of high speed steel, mild steel and Aluminum was examined forRockwell Hardness Test - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes Experiment No. 2 which measures the Rockwell hardness of steel, copper, brass and aluminum specimens. It explains that Rockwell hardness is determined by the depth of penetration of an indenter under specific loads. For steel, a tungsten ball .The modern Rockwell Hardness Testing machine is fully automated and therefore needs very little user input. . brief introduction about Rockwell Hardness test and also explained how the test conducted and what the principal of the Rockwell Hardness test. Under the discussion the results which were obtained the experiment are compared with the .

hardness measurements as a function of distance from the quenched end as obtained from the Jominy test. Module Procedure: 1. Discussion 1. When is hardness important? Hardness indicates resistance to deformation, so anytime a load is applied, hardness is important. When we think of hardness we usually think about a hammer or a knife, but resistance

rockwell hardness tester least count

Trilegal Tchê. Trilegal Tchê é diversão e prêmios para toda fa.

rockwell hardness test lab report discussion|rockwell hardness test calculation